Microelectronics and Devices

The invention of transistors in the early 1900’s has led us to the adventure of integrated circuits, resulting in the new era of electronics. This changed human life dramatically. We can’t imagine life without electronics such as appliances, smart phones, navigations and computers. However, some of them are completely new to us. For example, smart watches are able to monitor individual health continuously by integrating highly sensitive biosensors.

Microelectronics is a technology that integrates multiple devices into a small physical area and students in this area study electronic materials, microfabrication technologies, and physics of electronic devices. Microelectronics is a core technology when it comes to the development of new devices. Hence, students can build their career in many different engineering disciplines such as electrical, mechanical, chemical, and biomedical engineering.

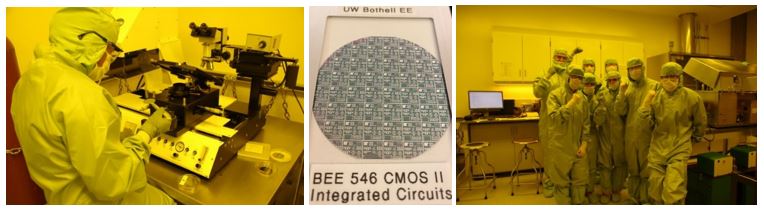

The UW Bothell ECE graduate curriculum includes courses on complementary metal oxide semiconductor (CMOS) technology, microelectromechanical systems (MEMS) and biomedical microsystems. B EE 546 and B EE 546 cover basic and advanced concepts in CMOS technology by offering circuit analysis, fabrication technology, and characterizations. B EE 545 covers physics and characters of basic CMOS circuits, the fundamental fabrication technologies for CMOS-based integrated circuits, and measurement characterization for CMOS inverters; and B EE 546 covers advanced concepts and provides hands-on laboratory experience for fabrication and testing of CMOS transistors. B EE 551 covers the basics of MEMS including micro-actuators, micro-sensors, micro-motors, principles of operation, different micromachining techniques (surface and bulk micromachining), IC-derived microfabrication techniques, and thin-film technologies as they apply to MEMS. B EE 522 covers multidisciplinary knowledge in microfabrication, sensor development, and surface modification essential for designing and implementing biomedical devices and systems. For deeper knowledge, students are encouraged to pursue B EE 600 Independent Study or B EE 700 Thesis with a faculty member.

Career Pathways

Experiences from classes in this key focus area of Microelectronics and Devices will prepare students for employment in this field in several capacities. Students should be prepared for competitive consideration of employment positions such as:

- Process Engineer

- Semiconductor Process Engineer

- Process Engineer

Faculty in Microelectronics and Devices Electronics

Research at UW Bothell

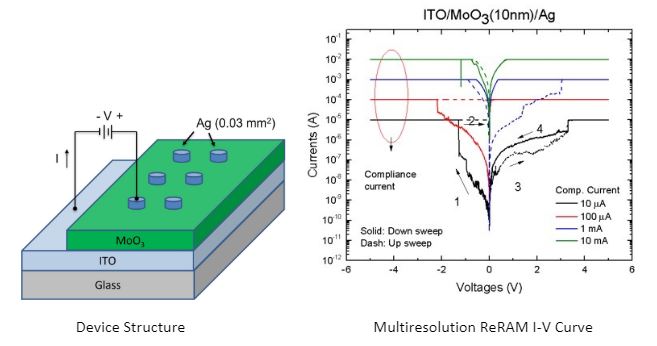

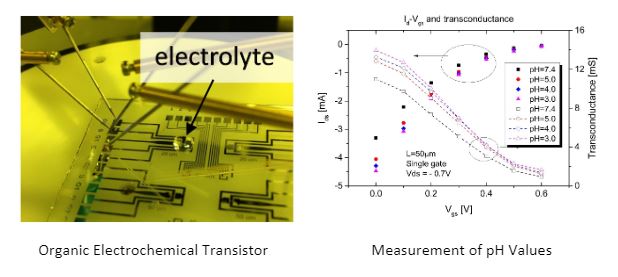

Dr. Seungkeun Choi pursues several research projects based on MEMS and microfabrications to develop modern electronic devices such as solar cells, sensors/actuators, and resistive memory devices.

- Project 1 – Resistive Random Access Memory (ReRAM): A resistive switching memory device is an emerging technology due to its fast-switching operation, longer retention time, high storage density, and low power consumption. In addition, it has a very simple structure in which a resistive layer is sandwiched between two electrodes. Furthermore, capability of multilevel switching has drawn a great interest due to particularly the increasing demands for high-density data storage. Tunability of multilevel resistance states allows a single memory cell to save more than 2-bits of information, hence, enabling high density and miniaturization memory cell implementation. In this research, the multilevel switching of a molybdenum oxide (MoO3)-based resistive memory device with ITO/MoO3/Ag structure will be demonstrated by setting different compliance currents. Furthermore, dependence of resistance states and set- and reset-voltages on the MoO3 thickness will be characterized.

Learn more in a presentation from Dr. Choi and MSEE Candidate Moosa Raza on the topic of “Next generation memory technology: a Resistive Random-Access (ReRAM) Memory.”

- Project 2 – Organic Electrochemical Transistor Sensors: The rising field of bioelectronics, which couples the realms of electronics and biology, holds great potential for the development of novel biomedical sensors and devices. Particularly, organic electrochemical transistors (OECT) have received great interest due to their potential usefulness as a sensor for various biological/chemical sensing application. In this research, an electrochemical transistor based on pedot:pss electrode will be demonstrate as a biological sensor. Furthermore, the sensor will be integrated with portable electronics for sensing and data management.

Study Microelectronics and Devices

The curriculum reflects depth and breadth of faculty research expertise and provides graduate students with a solid foundation in power systems, renewable energy, and power electronics. Relevant courses include:

- B EE 545 Complementary Metal Oxide Semiconductors (CMOS) I

- B EE 546 Complementary Metal Oxide Semiconductors CMOS II

- B EE 551 Introduction to Microelectromechanical Systems (MEMS)

- B EE 552 Biomedical Microsystems

Learning objectives

In this technical area, students will learn:

- Complementary Metal Oxide Semiconductor (CMOS) technology including circuit analysis, fabrication technology, and characterizations. Topics include physics and characters of basic CMOS circuits, the fundamental fabrication technologies for CMOS-based integrated circuits, and measurement characterization for CMOS inverters.

- How to fabricate CMOS integrated circuits in the state-of-the-art UW Bothell cleanroom. CMOS inverters, a ring oscillator, and digital logic gates are fabricated and tested. Various CMOS fabrication technologies and equipment are used including a mask aligner, furnace, metal sputter, spin-coater, profilometer, and semiconductor analyzer.

- Basics for microelectromechanical devices and systems including micro-actuators, micro-sensors, and micro-motors, principles of operation, different micromachining techniques (surface and bulk micromachining), IC-derived microfabrication techniques, thin-film technologies as they apply to MEMS.

- Multidisciplinary skills in microfabrication, sensor development, surface modification essential for designing and implementing biomedical devices and systems. Specific real-world systems are fabricated, characterized and optimized.

Emphasis on project-based learning through class projects

Many of the courses listed above provide class projects that will enhance student learning. Particularly, students in a team-oriented project learn important skills such as collaboration, communication, and presentation.

[B EE 545] Complementary Metal Oxide Semiconductors (CMOS) I

A project will be given at the beginning of the 7th week. This is a team project which comprises two or three students aiming to understand how to fabricate various semiconductor-based electronic devices. Suitable topics will be provided. By actively engaged in this project, students practice how to apply what they learn during the class in order to understand modern electronics such as piezoelectric accelerometers, thermoelectric generators, tactile sensors, and so on. Students are expected to read a research article, create a power point slide, and present it to explain fabrication process in detail.

[B EE 546] Complementary Metal Oxide Semiconductors (CMOS) II

This course is the second in the two-course CMOS technology series. This course emphasizes and provides hands-on lab experience for fabrication and testing of CMOS transistors. The course engages students in modern CMOS fabrication and characterization. Lectures provide fundamental theory and physics for various fabrication processes. Students will fabricate CMOS inverters and test them to characterize their performance. Students will learn how to use various equipment including mask aligner, furnace, metal sputter, spin-coater, and so on. Topics for the CMOS fabrication technology include photolithography, oxidation and diffusion, etching, thin film deposition, and chemicals and materials. Topics for measurement characterization include analysis of I-V and C-V curves for a CMOS invert and thin film thickness measurements.