According to the Centers for Disease Control and Prevention, about 695,000 people died from heart disease in 2021 — which is one in every five deaths in the United States, making it the leading cause of death for people of most racial and ethnic groups.

Heart disease is most commonly detected through an electrocardiogram, a simple test that checks heart rhythm and electrical activity. “Sensors called electrodes are attached to the skin and are used to detect the electrical signals produced by a person’s heart each time it beats,” said Vi Nguyen, a senior in the University of Washington Bothell’s School of STEM. “These signals are recorded by a machine and are reviewed by a doctor to see if they indicate something unusual.”

The test itself is relatively short and straightforward, but it also can be a bit uncomfortable. “The test involves attaching electrodes to a person’s arms, legs and chest using a gel that contains many chloride ions which allows electron conduction from the skin surface to the ECG machine,” Nguyen, an Electrical Engineering major, explained. “Even though it’s not painful, the gel is cold and sticky, and can often irritate people’s skin.”

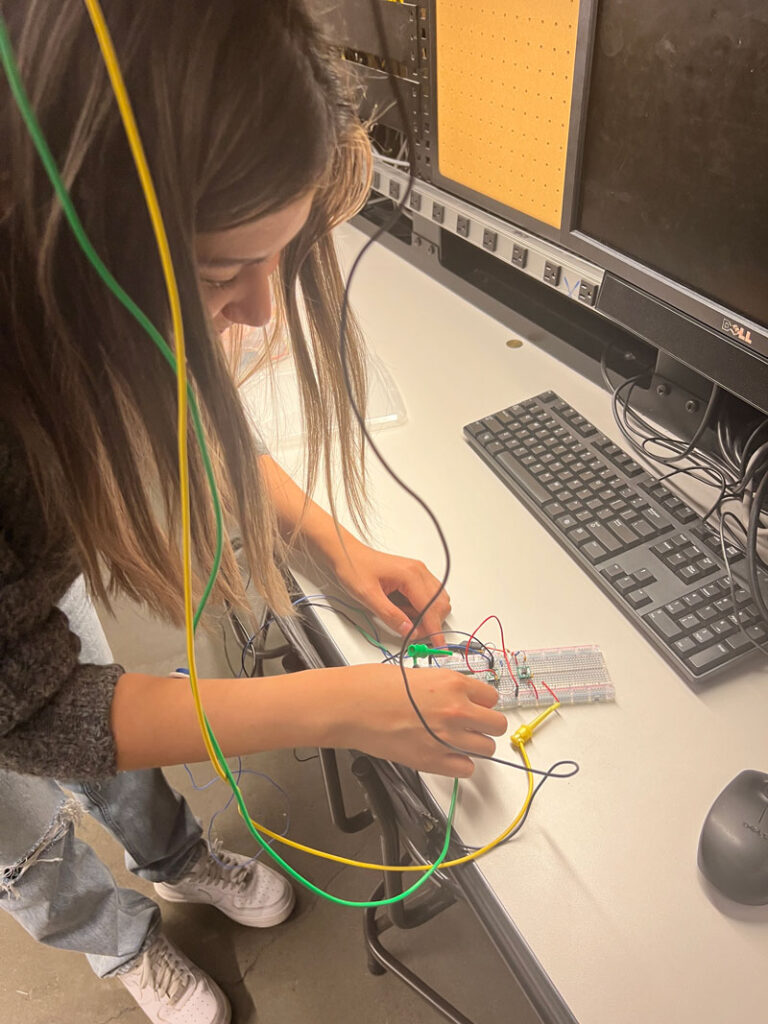

Wanting to improve ECG recording methods, Nguyen developed non-contact electroencephalography and electrocardiography electrodes — or, in other words, electrodes that do not require the use of gel. Her research was supported by a Founders Fellows Summer Research Stipend.

Executing the electrodes

Traditional electrodes for ECGs are made of silver, but Nguyen made hers out of copper. “It is more cost effective, and the presence of a large number of free electrons in copper makes it a good conductor of electricity,” she said.

Ngyuen cut a one-inch circle out of a copper sheet and soldered it onto a wire to create the left arm electrode and then repeated the same process to create the right arm electrode. “I had never soldered anything before, let alone something so small,” she said. “It required the use of a reflow oven, which I’ve never used before. The process definitely took a lot of trial and error.”

The risk of failure, however, also sparks the chance of discovery. “The most rewarding part of this research was learning how to problem solve on my own,” Nguyen said. “I gave myself permission to make mistakes and learn from them — and that made it all the more exciting when I finally got it right.”

She celebrated her success by testing the soldered electrodes on a classmate’s arms. The data picked up by the electrodes was displayed on an Arduino Uno, an open-source microcontroller board that Nguyen programmed to show heart rate. “Unfortunately, the copper electrodes picked up too much noise from both inside and outside of the body, and I was not able to get a clear read of the heart rate,” she said.

The most rewarding part of this research was learning how to problem solve on my own. I gave myself permission to make mistakes and learn from them — and that made it all the more exciting when I finally got it right.

Vi Nguyen

Getting the heart to chart

Disappointed but not deterred, Nguyen decided to create a copper shield for the electrode. “My hope was that the shield would block out the surrounding excess noise and only pick up the signal that is making contact with the electrode, which would be the person’s heartbeat,” she said.

The shield consisted of copper braided mesh tubing and a copper sheet that was large enough to cover the electrode. When implemented, Nguyen was able to see slight signals from the ECG but only if she pressed down substantially on the electrodes so that they made intense contact with the skin. Still, she said, “the signal also did not appear consistently. While it was better than before, there was definitely still need for improvement.”

Nguyen’s determination to learn from the research process made an impression on Dr. Kaiboa Nie, associate teaching professor in the School of STEM and Nguyen’s mentor for this project.

“Vi did a fantastic job learning and investigating how to create capacitive electrodes with amplifiers for measuring ECG signals from the human body,” Nie said “The project offered her a great opportunity to explore biomedical research and apply what she learned in electrical engineering classes to real biomedical applications.

“This could also help prepare her for a career in biomedical sciences and engineering.”

Refusing to take a beat

Indeed, Nguyen plans to continue her research into this project.

“I faced many challenges and even had difficulties in ordering components quickly,” she said. “But I am excited to continue refining the non-contact ECG.”

Nguyen’s next steps include improving the amplifier to help intensify the signal of the heartbeat and reduce excess noise as well as discovering a more effective way to hold the electrodes in place.

“I am working toward a better non-contact ECG electrode that makes monitoring ECG more user friendly and accessible,” Nguyen said. “I hope it can one day help people who need frequent heart monitoring and make their lives at least a little bit easier.”